"Framework"

"Framework"

| Home |  |

| Instrument |  |

| About me |  |

| Thanx |  |

| Contact |  |

Binding Part III

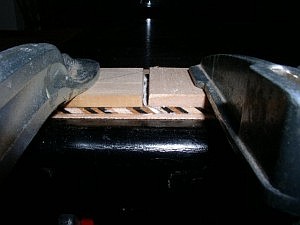

Cutting the first block into slices of |

|

|

The slices are glued successively onto veneer, trued, glued topsyturvy and planed to thickness. |

|

| For the binding of the "F" holes, I plane the strips to 1.3 mm and cut them according to the width and length of each lamination mold. |  |

| Gluing the pre-bent strips over the lamination mold |  |

| The binding for the first "F" hole finished |  |

|

Sawing the "F" hole on the bass side |

|

Cleaning up the sawcut with a razor-sharp cutting-knife Now follows the fitting of the binding framing the "F" hole (thus "Framework"). |

|

completed "F" hole |

| Sides To increase the gluing surface between the sides and back resp. top, the linings are installed. I use unkerfed willow linings of 3.5 mm thickness. |

|

Finished sides The sides are cleaned on the inside, the back can be glued in position. |

|